projects & products

sweetworks.io - GreenHouse Sled - Accelerated Organic Growing & Natural Soil Strati

Discover more about our extensive range of professional services. We constantly update this page, but if you still can’t find what you’re looking for, please feel free to get in touch with us – we will be more than happy to help.

status quo:

Status Quo:

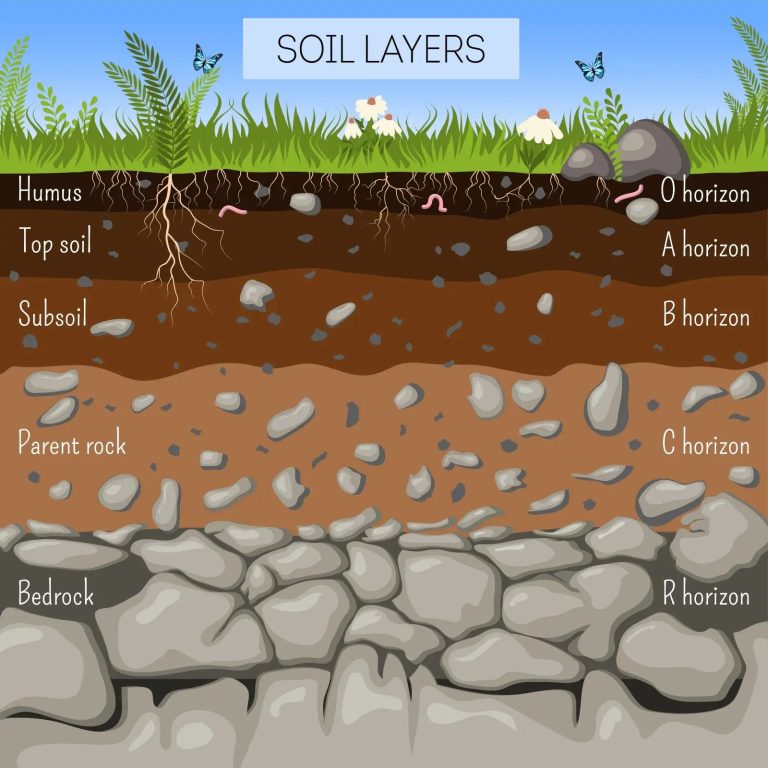

- microbiomes, minerals, enzymes, good insects as a result the natural bio-system gets destroyed from heavy tilling and contamination from pesticides (open air or in fixed greenhouses)

- fixed greenhouses destroy soil strati

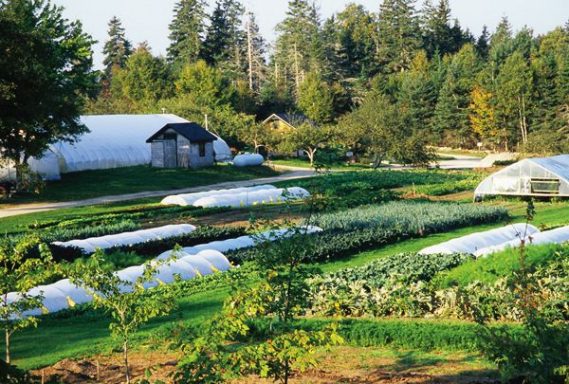

- short grow season in dry and cold climates without greenhouses

- cold snaps destroy crops and soil structure - reduced root structure and above ground frost damage without greenhouses

- lack of moisture due to evaporation and poor soil structure (ie. Living Soil vs Clay)

- operational expenditure is high in demobilizing and moving greenhouses - many small and large parts/devices.

inertia:

- Dead Natural Systems - we need to bring the natural systems back to life.

- fixed greenhouses need a lot more external inputs to get any output.

- 0, A and B horizons are completely dead and is incapable of sustaining life without chemical and GMO additives.

- Trap the moisture locally

- well water normally has concentrated iron and a high concentration of good/bad minerals

- we need to extend grow season

- we want to diversify our crop depending on market requirements

- we need to reduce the operational cost in moving infrastructure to suit growing requirements.

innovation:

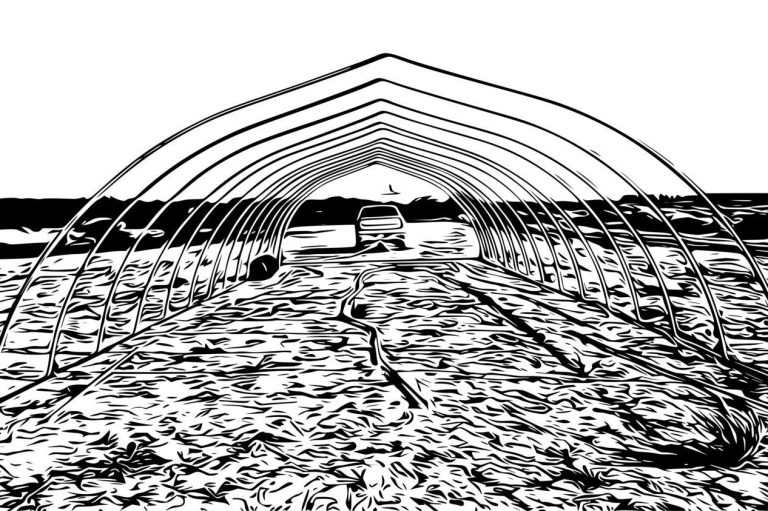

Don't move the soil - move the greenhouse - drastically improving living soil health, reducing operational costs and improving output.

Cycling greenhouse locations allows you to rebuild the soil structures while taking full advantage of the terrestrial foot print. ie. planting high yield in greenhouse and mid yield in open air shifting locations year to year - leave the root structure and organic materials in the ground once harvested.

Rain water open to soils and atmospheric ionization.

Maintain natural web of life practices - ecosystem thinking but give mother nature a boost by creating micro managed natural contained systems.

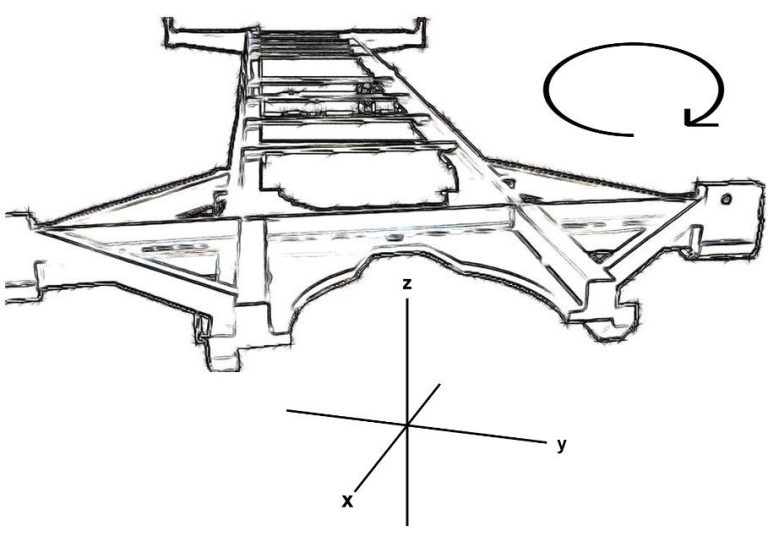

Like all of our industrial/commercial innovations we always pursue faster tactical de-mobilization and mobilization techniques. Pulling a sled is far simpler than fully deconstructing a greenhouse and moving. With our system you can leave all watering, lighting and hvac systems in place.

innovation:

As a result our soils are now alive and our yield is far higher per square foot.

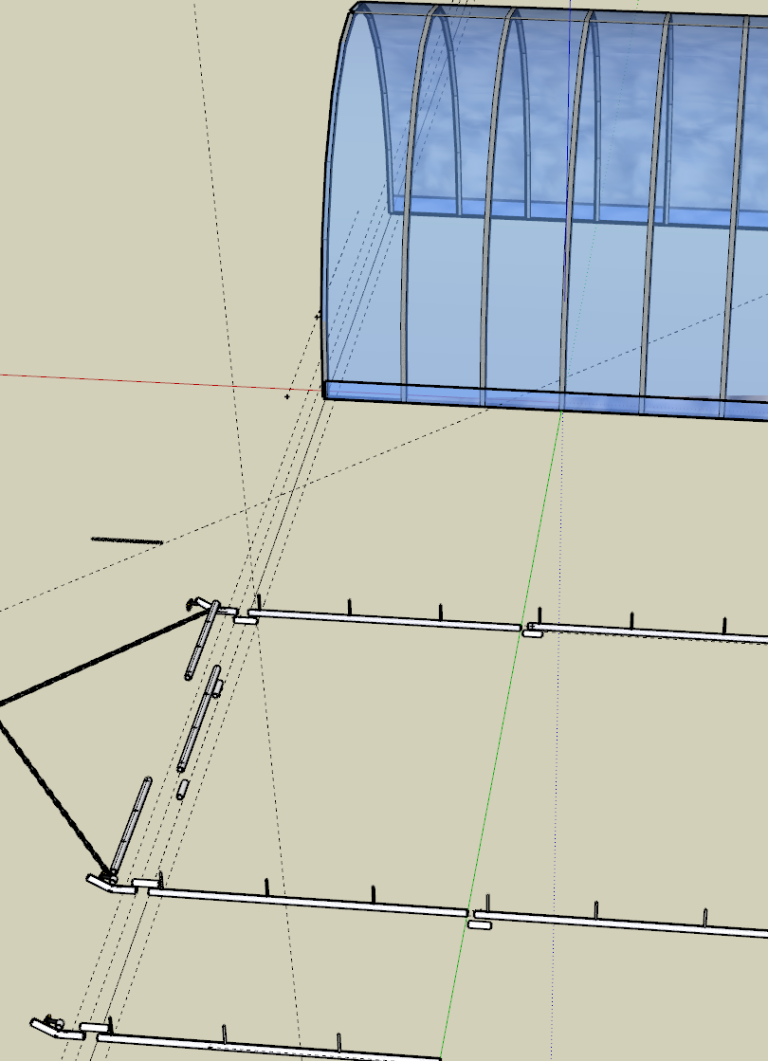

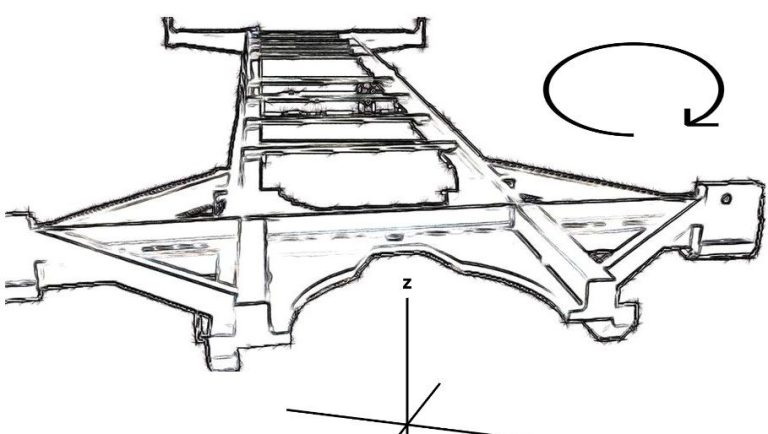

Creating a sled that sits beneath the entire length of the greenhouse (250ft +) we can easily pull the entire structure with most machinery (atv, tractor, truck etc). The sled had to be strong enough to take the torsion of the pulling and sliding as well as being able to be fastened down when stationary due environmental factors (winds, rain, hail, snow etc)

innovation:

Our backgrounds in heavy machinery and industrial design proved well in this case as we were able to build an simple solution that can fit in the bed of a pickup truck but has the functional capability to overcome a lot of the physical forces.

Appropriate crossbar design that is easily demobilized and the sled skies are built into the system.

innovation:

We went through many iterations before we met all design needs to support all greenhouse agri tech applications.

Addressing easy assembly, easy transport and strength & longevity requirements.

inspiration:

The current sled kit is made to 48" on center commercial greenhouses but we can BTO for other dimensions.

The entire system is easily pinned together and can be modified in length in a few minutes.

Simple helical screws and chain can be used to fasten the structure down. Cisterns and water catchment systems can also be used to weigh the structure in place. (Ask about GreenHouseCistern kit by SweetWorks.io) .

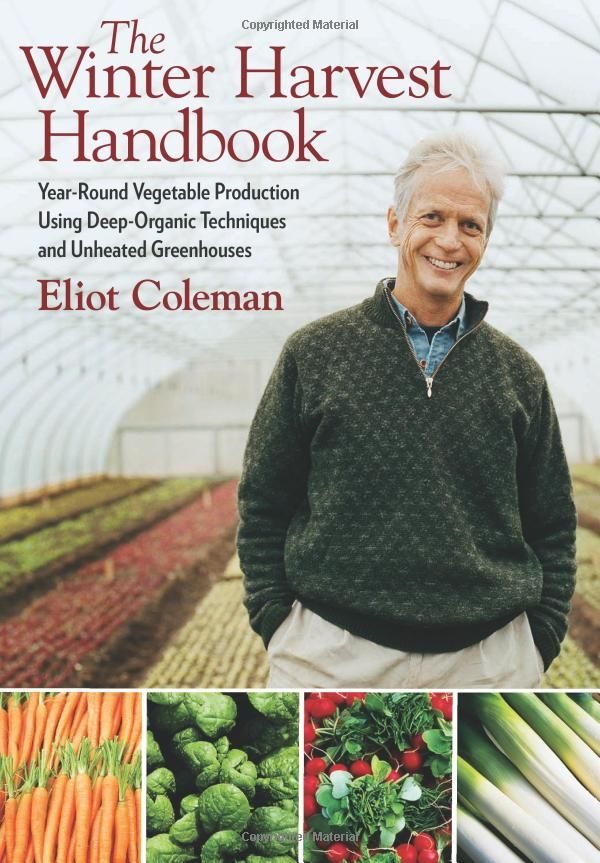

inspiration:

Inspired by Eliot Coleman - https://www.eliotbarbara.com/

1. Classical organic farming is based upon the creation and maintenance of a biologically active fertile soil.

2. Organic farming succeeds because of the benefits derived from that soil. We focus on correcting the cause of pest problems (weak plants) by creating optimum soil conditions to strengthen the plant, rather than merely treating the symptom (pest damage) by trying to kill the pests that are attracted to weak plants. The production of pest-free plants and livestock with active immune systems is a direct outcome of this type of farming that, as scientific studies have consistently shown, induces pest and disease resistance in the crops.

3. Research into the marvelously complex soil micro-biome is revealing the vital ecological processes that support natural non-chemical food production. That research underscores the intuitive brilliance of the founding organic farmers.

4. As a bonus, fertile soil produces food of the highest nutritional quality. This was the foremost initial aim of the soil care techniques that became organic farming.

5. Long-term soil productivity does not require fertilizer inputs from off the farm. It can be maintained by the use of farm-derived compost, crop rotations, green manures, cover crops, nitrogen-fixing legumes, grazing livestock, shallow cultivation, enhanced biodiversity and other time-honored practices that nurture the boundless energy and logic of the earth. Organic farming is a circle of endless renewal and it will succeed wherever there is soil.

6. The inclusion of deep-rooting forbs in rotationally grazed grass/legume pastures within the rotation helps to maintain fertility and make available the almost inexhaustible mineral supply from the lower levels of the soil. Grazing livestock benefit the soil; diverse pasture benefits the livestock.

7. Most significant of all, since soil fertility on the organic farm is not powered by purchased fertilizer inputs but, rather, by easily understood and universally applicable soil management practices, this food production system is accessible at no cost by farmers everywhere and can thus nourish the planet with exceptional food in perpetuity. That clear path to a bounteous well-fed future for humankind will remain unrealized if we allow any misunderstandings about – and subversions of – the foundational concepts of real organic farming to go unchallenged.

boks.ltd - the böks sled

Field tested for years in the worst of conditions our boks sea container sled is a device developed to be mounted under sea containers to the CSC/ISO mount point on the corner blocks of any sea container. It operates as a sled/sleigh carrying empty or fully loaded sea containers in a drag, lift, slide function. The boks sea container sled ensures that the following aspects of moving and handling sea containers are addressed.

sweetworks.io & böks.ltd - onsite hazardous containment application - Electrical Transportation & Recreational Device Storage and Charging

Addressing an issue that is proving to be a danger in society. Volatile battery and component charging and storage.

status quo:

- low/medium/high volume housing and commercial real-estate are filled with high amperage rec vehicles that tenants store in areas that can damage the structure in the event of a battery ignition.

- almost impossible to police as many of the devices have removable high capacity batteries that can be brought inside and charged.

- unknown certification processes around the technology

status quo:

- cheap non oem battery replacements are often purchased that do not meet the oem standards

- addressing an insurance nightmare that is on our doorstep and is very difficult to manage

- human behaviour dictates mistakes will be made in handling these materials and devices

- portable batteries are also an issue as they can be placed in bags and be impossible to track via security

status quo:

- elevators become a trap especially in cases where sudden ignition takes place of portable device batteries

- the technology has not been around long enough to ensure conditional changes like humidity, temperature, pressure and even electronic field changes do not affect the battery technology doesn't become volatile

- consider workplaces as well as often people will bring their batteries into the office and plug in the charger beneath their desks or in a cafeteria

status quo:

- considering high density of todays society an simple battery fire can lead to a catastrophic event

- when the firecodes were created they did not address things like volatile battery in living and workspaces

- a battery fire with standard supression can actually enhance the fires especially for lithium ion; where water excites the fire rather than supressing it

status quo:

- high capacity battery technologies are often in:

-- bicycles

-- scooters

-- skateboards

-- motor chairs

-- one wheels

- charge locations are often oversight by most people

status quo:

- when charging these batteries they must be kept in a temperate conditions; ie. stuffing in a closet is not the right way of storage or charging in this case

- also the amount of combustibles in most living spaces is much higher as compared to even a decade ago where everything is a synthetic combustible material

- there is a lot of room for regulation in this area and has been an oversight for the last decade as technology rapidly advances in mobility for people

inertia:

- a solution that can be easily deployed for static or moveable needs on any surface (boks sled)

- protect the super structure of the storage solution from corrosion and rott (boks sled)

- deployment - a solution that can be placed indoor and outdoor (boks)

- baseline/standards - a solution that will conform to all major standards and meet insurance standard requirements; industrial burn rating

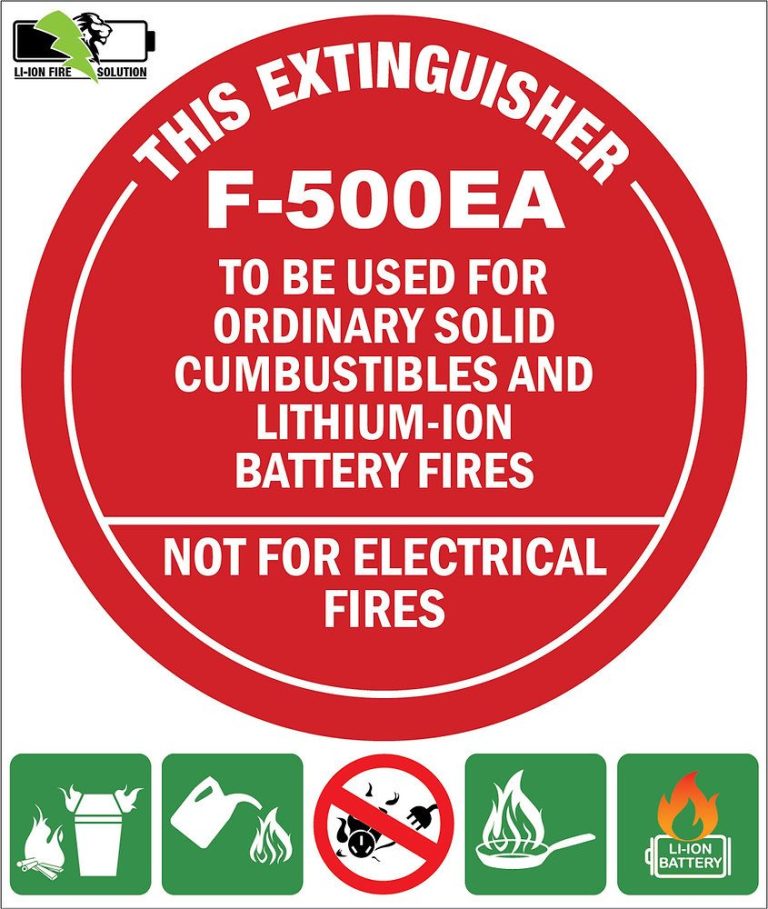

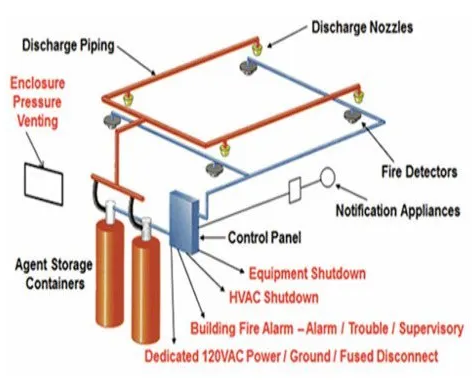

- baseline/standards - a solution that will conform to fire systems standards; hose bib, f-500 fire suppression systems (boks), built in redundant alarm/alerting application

- reduce theft - a solution that is secure (boks); video security, hardened fire rated door, swipe and secure building system access

- environmental needs - temperature control management to limit overheating

- cold\hot climates - optional lined internal insulated burn proof application

- environmental/visual/architectural - optional external cladding to meet onsite design requirements

- electrical charging needs - high capacity 210-240v 40A (8500W) for multiple charging applications; optional monitored electrical draw

- need appropriate hanging and storage footprint for hardware

- need appropriate solution for locking hardware to superstructure

innovation:

- the solution must be able to sit in a parking lot, on loose materials, placed on lawns, be able to be dragged to a location; we propose that a boks sled would work in this case. https://www.boks.ltd/boks-sled/

- by using the boks sled we can ensure that the super structure can withstand all the elements as well as provide clearance to prevent rotting and corosion by keeping enough moving air beneath the super structure. https://www.boks.ltd/boks-sled/

innovation:

- deployment - the containment system can be lowered into parking lots during construction being built into the early stages of construction or rolled into underground facilities using standard dolly wheels.

- most shipping containers have an excellent burn rating since the application in shipping and haulage has a high fire safety and overall ISO standard

innovation:

- incorporating an optional f-500 fire supression system will ensure that the system has the cability to address any current or future battery technologies

innovation:

- systems alerting both audible and application for IOT systems escalation built into onsite building management services application

- built in hose bib for onsite fire suppression by firetruck or hydrant

innovation:

- optional surveillance system for external and internal security

- optional hvac depending on your requirements

- optional IOT systems (ie pollution, weather, environmental monitoring)

- optional wireless integration into main system

- optional external cladding to meet onsite design/build/architectural requirements

- optional mag/strike lock system for tie into building access management system.

innovation:

- external electrical connection junction box

- optional external high amperage plug for moveable solution

- high capacity 210-240v 40A (8500W) for multiple charging applications; optional monitored electrical draw

- ie. 17 electric wheeled aplications with a 500W (5A) charger per.

innovation:

- fireproof industrial insulated door with security cage

- frame welded and re-enforced into sea container superstructure

innovation:

- solar solution to power internal systems in the event of power failure

- grid tie application to offset the charging draw

innovation:

- optional solar venting

- solar powered motion activated lighting (external and internal)

innovation:

- optional fire rated windows and security cage

- optional HVAC system with protective shield

- optional externally mounted electrical connection

innovation:

- integrated e-track for hanging

- integrated e-track for locking devices inside container

- optional shelving for layering charge and storage stations

- optional lined internal insulated burn proof application to enhance current burn rating as well as keeping internal temperature temperate

1/2 Hazardous Containment 1/2 Work Area Storage

Example of mixed build requirement working with www.boks.ltd

©Copyright. All rights reserved.

sweetworks.io

We need your consent to load the translations

We use a third-party service to translate the website content that may collect data about your activity. Please review the details in the privacy policy and accept the service to view the translations.